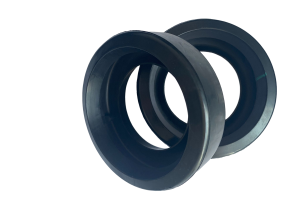

Reducing Pipe Fittings Rubber Sealing Gasket

Product Introduction

Rubber seal gaskets work by filling the space between two surfaces, providing a cushioning effect that prevents fluids or gases from leaking out. The flexibility and resistance to compression of rubber make it an ideal material for creating a tight seal under pressure or vibrations. The gasket can be used in both static and dynamic applications, with varying degrees of hardness and thickness depending on the specific use case.

Rubber seal gaskets are available in a variety of shapes, sizes, and materials to meet different sealing requirements. They can be made from natural rubber or synthetic rubber compounds, including silicone, EPDM, neoprene, and nitrile rubber. Each material offers unique properties and resistance to chemicals, heat, and weathering, making them suitable for different applications.

Rubber seal gaskets are an essential component in many industries and applications, providing a reliable and cost-effective solution for creating a secure and leak-free seal.

Product Features

1. Versatility: Rubber seal gaskets can be used in a wide range of applications due to their capability to accommodate various shapes and sizes. They can be molded and cut to very precise tolerances.

2. Resilience: The rubber material in a gasket allows it to deform under pressure or compression, then return to its original shape, even after repeated use.

3. Durability: Rubber seal gaskets can withstand exposure to various environments, such as high temperatures, gases, chemicals, oils, and UV radiation.

4. Flexibility: Rubber seal gaskets can flex and bend according to the shape of a surface, ensuring a tight seal between components.

5. Corrosion resistance: Depending on the type of rubber, a gasket can maintain its structural integrity and resist wear and tear.

6. Non-conductive: Rubber gaskets are non-conductive, making them an excellent choice for use in electrical systems.

7. Noise and vibration reduction: Rubber seal gaskets can absorb noise and vibration by cushioning components, making them beneficial in mechanical systems.

8. Cost-effective: Rubber seal gaskets are relatively inexpensive compared to other sealing materials, making them a cost-effective option for various industries.

9. Easy to install: Rubber seal gaskets can be installed quickly and effortlessly, reducing downtime in machinery and boosting productivity.

Overall, our rubber seal gaskets can offer a range of features that make them a versatile and reliable sealing solution for a wide range of applications across different industries.

Details

Place of Origin: Shandong, China

Brand Name: ZDSY

Model Number: 33-610, Customized

Processing Service: Moulding

Material: Silicone, EPDM, NBR or Customized

Size: 33-610

Color: Black or Customized

Application: For Fire Pipe or Industries

OEM: Aviable

Quality: 100% Professional Test

Feature:Heat & Chemical Resistance

Packing: PE plastic bags then to the carton or as per your request

Applications

1.Fire main system

2.City water supply pipe network

3.Chemical and industrial piping systems

4.Piping system for military ships

5.Mine water supply and drainage

6.Petroleum industry pipeline system

They can keep pipes without leaking.

EPDM rubber own good anti-aging.

Its service life is more than 15 years.

* Easy Installation

* Good Anti-aging

* Reduce noise and vibration

How to Select Rubber Materials for Seals

In the selection of rubber materials for seals, we must consider several important indicators:

I.Consideration of use conditions

1.Objects to be touched (including liquid, gas, solid and various chemical agents)

2.Range of Temperature (lowest and highest temperature)

3.Range of Pressure (Minimum compression ratio of seals under pressure)

4.Static or dynamic using considerations

II.Consideration of design requirements

1.Combination of consideration

2.Consideration of possible chemical reactions in use

3.Consideration of service life and review of possible failure cause

4.Consideration of component lubrication and assembly method

5.Consideration of tolerance

III. Consideration of inspection requirements

1. Define inspection criteria

2. Determine confirmation of the need for sample

3. Set the acceptable criteria

4. Main sealing surface setting

IV. Selection of material specifications

1. Determine the selection of material specifications, such as ASTM, DIN, JIS, etc.

2. Discuss with suppliers. Define the selection of rubber materials.

3. Choose the supplier with good quality and maintain stability of the supplier.

V. Cost considerations

Choose suitable materials, to avoid improper rubber materials with high cost, causing the products cannot perform the sealing function. Both natural and synthetic rubbers have common rubber properties, such as resilience after compression, flexure resistance, compression resistance and permeability to gas and liquids.

Each type of rubber elastomer has its unique properties. At the same time, the rubber composition can also affect its properties. At present, there are more than 20 kinds of rubber elastomers, and they are widely used in all kinds of material needs. In addition, through the professional mixing refinery formula design and mixing, it can provide more in line with the needs of various projects. At the same time, vulcanization transforms rubber from a thermoplastic mixture into a thermosetting shape. Crosslink provides rubber molecular chain strength and elasticity to the performance of seals. Therefore, the seal designer needs to discuss with the sealant builder and the sealant supplier for the materials to be used.

Working Conditions of Rubber Materials

|

Group of Rubber |

Range of Hardness (Shore Type A) |

Properties of Rubber |

Working Pressure MPa |

Working Temperature (°C) |

Working Medium |

|

I -1 |

HS65±5° A |

Oil Resistance |

<8 |

-35〜+100 |

|

|

I -2 |

HS75±5° A |

<16 |

-30〜+100 |

Mineral Oil, Air, Water |

|

|

I-3 |

Oil Resistance &Low Temperature Resistance |

<16 |

-40〜+100 |

||

|

I -4 |

HS85±5° A |

Oil Resistance |

<32 |

-25〜+100 |

|

|

II-1 |

HS65±5° A |

Oil Resistance &High Temperature Resistance |

<2 |

-20〜+220 |

|

|

II-2 |

HS75±5° A |

<16 |

|||

|

III-1 |

HS65±5° A |

Acid and Alkali Resistant |

20% Sulfuric Acid 20% Salt | ||

|

III-2 |

HS75±5° A |

<2 |

-25〜+80 |

20%Na0H | |

|

III-3 |

HS85±5° A | 20% Potassium Hydroxide |

Note: This standard specifies the classification and requirements of rubber materials for day motion sealing belts on the financial emergency system when oil-based hydraulic oil and lubricating oil are used.

【1】 The material of each compound is not specified clearly. Group I can be nitrile butadiene rubber; Group II can be fluoro rubber; Group III can be natural rubber or choose appropriate materials; Example: Ethylene Propylene Rubber (EPR, EPDM), neoprene rubber, butyl rubber, etc.

【2】 In our country, the standard of the hardness of Shaw Type A in the rubber industry, polyurethane industry, and plastic industry is all same. The rubber materials of reciprocating motion sealing rings specified in this standard are divided into A and B categories. Type A is the nitrile rubber material, and Type B is the castable polyurethane rubber material. Type A is butyl-wax rubber material based, and type B is cast-polyurethane rubber material based.

|

Chinese Name |

English Name |

Code Names |

ASTM Code |

|

天然橡胶 |

Natutal Rubber |

NR |

AA |

|

异戊橡胶 |

Poly isoprene Rubber |

IR |

AA |

|

丁苯胶 |

Styrene butadiene Rubber |

SBR |

AA |

|

顺丁胶 |

Polybutadiene Rubber |

BR |

AA BA |

|

丁基橡胶 |

Butyl Rubber |

HR |

BA |

|

乙丙胶 |

Ethylene propylene Rubber |

EPDM |

AA BA CA DA |

|

氯丁胶 |

Polychliroprene Rubber |

CR |

BC BE |

|

丁腊胶 |

Nitrile Rubber |

NBR |

BF BG BK CH |

|

聚氨酯胶 |

Polyurethane Rubber |

PU |

BG |

|

氯磺化聚乙烯胶 |

Hypalon. Polyethylene |

CSM |

CE |

|

丙烯酸酯橡胶 |

Polyacrylate Rubber |

ACM |

DF DH EH |

|

氯醇橡胶 |

Epichlorohydrin Rubber |

ECO |

CE |

|

乙烯-丙烯酸胶 |

VamacfEthylene/Acrylic) Rubber |

E/A |

EE |

|

硅橡胶 |

Silicone Rubber |

SI |

FC FE GE |

|

氟素橡胶 |

Fluoro Carbon Rubber |

FPM |

HK |

|

氢化丁腈橡胶 |

Hydrogenated Nitrile Rubber |

HNBR |

DH |

|

氟素硅胶 |

Fluorinated Silicone Rubber |

FLS |

FK |

Applicable Working Pressure of Each Hardness Rubber O-rings

| Hardness (Shore Type A) |

60±5°A |

70±5°A |

80±5°A |

90±5°A |

| Static Seal Working Pressure /MPa |

1 |

10 |

20 |

50 |

| Reciprocating Sealing Working Pressure/MPa Reciprocating Velocity <0.2m/s |

1 |

8 |

16 |

24 |

Rubber Materials Properties

|

NR |

IR |

SBR |

BR |

IIR |

EPDM |

CR |

NBR |

PU |

CSM |

ACM |

ECO |

VAE |

SI |

FPM |

|

| Tensile strength |

◎ |

• |

• |

△ |

△ |

△ |

• |

• |

◎ |

• |

▼ |

△ |

• |

▼ |

• |

| Elongation |

◎ |

◎ |

• |

△ |

• |

• |

• |

• |

◎ |

• |

▼ |

▼ |

▼ |

◎ |

▼ |

| Rebound Resistance |

◎ |

◎ |

△ |

◎ |

▼ |

• |

◎ |

• |

◎ |

△ |

△ |

△ |

△ |

△ |

△ |

| Tear Resistance |

◎ |

• |

△ |

△ |

△ |

△ |

• |

• |

◎ |

△ |

▼ |

△ |

△ |

▼ |

△ |

| Abrasion |

◎ |

◎ |

◎ |

◎ |

◎ |

• |

• |

◎ |

◎ |

• |

△ |

△ |

• |

▼ |

△ |

| Impact StrengthResistance |

◎ |

◎ |

◎ |

• |

• |

• |

◎ |

• |

◎ |

• |

▼ |

• |

△ |

▼ |

△ |

| Gas Impermeability Resistance |

△ |

△ |

△ |

△ |

◎ |

△ |

◎ |

• |

• |

• |

△ |

◎ |

• |

▼ |

• |

| Oxygen Resistance |

△ |

△ |

△ |

△ |

◎ |

• |

• |

△ |

• |

◎ |

• |

• |

◎ |

◎ |

◎ |

| Ozone Resistance |

▼ |

▼ |

▼ |

▼ |

• |

◎ |

• |

▼ |

• |

◎ |

• |

◎ |

◎ |

◎ |

◎ |

| Weathering Resistance |

△ |

△ |

△ |

△ |

◎ |

◎ |

• |

△ |

• |

• |

• |

• |

◎ |

◎ |

◎ |

| Flame Resistance |

▼ |

▼ |

△ |

△ |

◎ |

◎ |

• |

▼ |

• |

◎ |

• |

• |

◎ |

◎ |

◎ |

| Heat Resistance |

▼ |

▼ |

△ |

△ |

• |

◎ |

• |

△ |

△ |

• |

• |

• |

• |

◎ |

◎ |

| Low TemperatureResistance |

• |

• |

△ |

• |

△ |

• |

△ |

△ |

• |

△ |

▼ |

• |

• |

◎ |

• |

| Oil and Fuel Resistance |

▼ |

▼ |

▼ |

▼ |

▼ |

▼ |

• |

• |

• |

■ |

• |

• |

△ |

△ |

◎ |

| Animal and VegetableOil Resistance |

△ |

△ |

△ |

△ |

• |

• |

• |

◎ |

• |

• |

◎ |

◎ |

△ |

■ |

◎ |

| Alcohol Resistance |

• |

• |

• |

• |

• |

• |

◎ |

• |

• |

◎ |

• |

• |

• |

• |

• |

| Alkaline Resistance |

△ |

△ |

△ |

△ |

◎ |

• |

◎ |

• |

▼ |

◎ |

▼ |

■ |

• |

▼ |

• |

| Acid Resistance |

• |

• |

■ |

■ |

• |

• |

• |

• |

▼ |

. |

△ |

△ |

△ |

△ |

• |

| Aliphatic solventResistance -Aliphatic |

▼ |

▼ |

▼ |

▼ |

▼ |

▼ |

• |

◎ |

• |

• |

◎ |

• |

△ |

▼ |

◎ |

| Aliphatic solventResistance- Aromatic |

▼ |

▼ |

▼ |

▼ |

▼ |

▼ |

△ |

• |

▼ |

△ |

△ |

• |

▼ |

▼ |

◎ |

| Oxygenated-solventResistance |

• |

• |

• |

• |

◎ |

◎ |

▼ |

▼ |

▼ |

△ |

▼ |

▼ |

△ |

△ |

▼ |

| Water Resistance |

◎ |

◎ |

• |

◎ |

◎ |

◎ |

• |

• |

△ |

• |

▼ |

• |

• |

• |

• |

Physical and Mechanical Properties of Polyurethane Elastomers

Physical and Mechanical Properties of Rubber Materials for Reciprocating Sealing Ring

| Groups of Rubber Materials | Universal Rubber MaterialsGroup Ⅰ | Universal Rubber MaterialsGroup Ⅱ | Universal Rubber MaterialsGroup Ⅲ | |||||||

| Ⅰ-1 | Ⅰ-2 | Ⅰ-3 | Ⅱ-1 | Ⅱ-2 | Ⅱ-3 | Ⅲ-1 | Ⅲ-2 | Ⅲ-3 | ||

| Low Hardness | Medium Hardness | Medium Hardness | High Hardness | Low Hardness | Medium Hardness | Low Hardness | Medium Hardness | High Hardness | ||

| Hardness (Shore Type A) | 65±5 | 75±5 | 75±5 | 85±5 | 65±5 | 75±5 | 65±5 | 75±5 | 85±5 | |

| Tensile Strength Mpa (≥) | 10 | 10 | 10 | 12 | 10 | 12 | 8 | 10 | 10 | |

| Elongation at Break % (≥) | 250 | 200 | 180 | 150 | 120 | 120 | 400 | 350 | 300 | |

| Permanent Set at Break % (≤) | 20 | 15 | 15 | 15 | 20 | 15 | 35 | 30 | 30 | |

| Permanent Deformation at Constant Compression% | Air at 100°C, 24h(compression rate 20%) | 50 | 55 | 55 | 50 | 70 | 70 | 70 | ||

| Air at 200°C, 24h(compression rate 20%) | 50 | 50 | ||||||||

| Brittleness Temperature°C (≤) | -35 | -30 | -40 | -25 | -20 | -20 | -30 | -30 | -25 | |

| Coefficient of Elongation and Aging | 100°C, 24h (≥) | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | ||

| 200°C, 24h (≥) | 0.85 | 0.85 | ||||||||

| Rate of weight change in oil resistance%120# Gasoline (7 parts) + Benzene (25 parts)(18~28°C)×24h (≤) | 20 | 20 | 20 | 15 | 10 | |||||

| Rate of Volume Change in Oil Resistance% | 20# Engine Oil(100±2°C)×24h(≤) | 6~8 | 5~7 | 5~7 | 5 | 2 | ||||

| 40-2Hydraulic Oil of Offshore Heavy Oil(100±2°C)×24h (≤) | 15 | 12 | 12 | 10 | 2 | |||||

| Coefficient of Acid and Alkali Resistance | 20% H2SO4 or HCI (18~28°C)×24h (≤) | 0.8 | 0.8 | 0.8 | ||||||

| 20% NaOH or KOH (18~28°C)×24h (≥) | 0.8 | 0.8 | 0.8 | |||||||

|

Table 1. Physical and Mechanical Properties of Natural Rubber Sealing Ring |

|||

|

Number |

Experimental Project |

NR |

|

|

1 |

Hardness/Shore A |

65±5 |

|

|

2 |

Tensile Strength/MPa |

≥17 |

|

|

3 |

Elongation at Rupture/% |

≥350 |

|

|

4 |

After hot air aging (70℃±2℃)×70h |

Rate of change in tensile strength/% |

≤-8 |

| Rate of change in elongation/% |

≤-10 |

||

| Rate of change in hardness/° |

≤+5 |

||

| Compression Set/% |

≤20 |

||

|

Table 2. Physical and Mechanical Properties of EPDM Sealing Ring |

|||

|

Number |

Experimental Project |

EPDM |

|

|

1 |

Hardness/Shore A |

65±5 |

|

|

2 |

Tensile Strength/MPa |

≥15.2 |

|

|

3 |

Elongation at Rupture/% |

≥400 |

|

|

4 |

After hot air aging (125℃±2℃)×70h |

Rate of change in tensile strength/% |

≤-20 |

| Rate of change in elongation/% |

≤-40 |

||

| Rate of change in hardness/° |

≤+10 |

||

| Compression Set/% |

≤30 |

||

|

Table 3. Physical and Mechanical Properties of NBR Sealing Ring |

|||

|

Number |

Experimental Project |

NBR |

|

|

1 |

Hardness/Shore A |

65±5 |

|

|

2 |

Tensile Strength/MPa |

≥15.2 |

|

|

3 |

Elongation at Rupture/% |

≥350 |

|

|

4 |

Resistant to No. 1 Standard Oil (100℃±2℃)×70h |

Rate of change in tensile strength/% |

≤-25 |

| Rate of change in elongation/% |

-15 ~ +15 |

||

| Rate of change in hardness/° |

-10 ~ +5 |

||

|

5 |

Rate of volume change(100℃±2℃)×22h Type A/% |

≤30 |

|

|

Table 4. Physical and Mechanical Properties of Silicone Rubber Sealing Ring |

|||

|

Number |

Experimental Project |

SI |

|

|

1 |

Hardness/Shore A |

60±5 |

|

|

2 |

Tensile Strength/MPa |

≥6 |

|

|

3 |

Elongation at Rupture/% |

≥300 |

|

|

4 |

After hot air aging (100℃±2℃)×70h |

Rate of change in tensile strength/% |

≤-15 |

| Rate of change in elongation/% |

≤-20 |

||

| Rate of change in hardness/° |

≤+10 |

||

|

5 |

Rate of volume change(200℃±2℃)×22h/% |

≤15 |

|